Matt Dunn’s Mountain Bike

Head tube (before gusset)

Internal cable port (rubber grommet fits in hole)

Large tire clearance

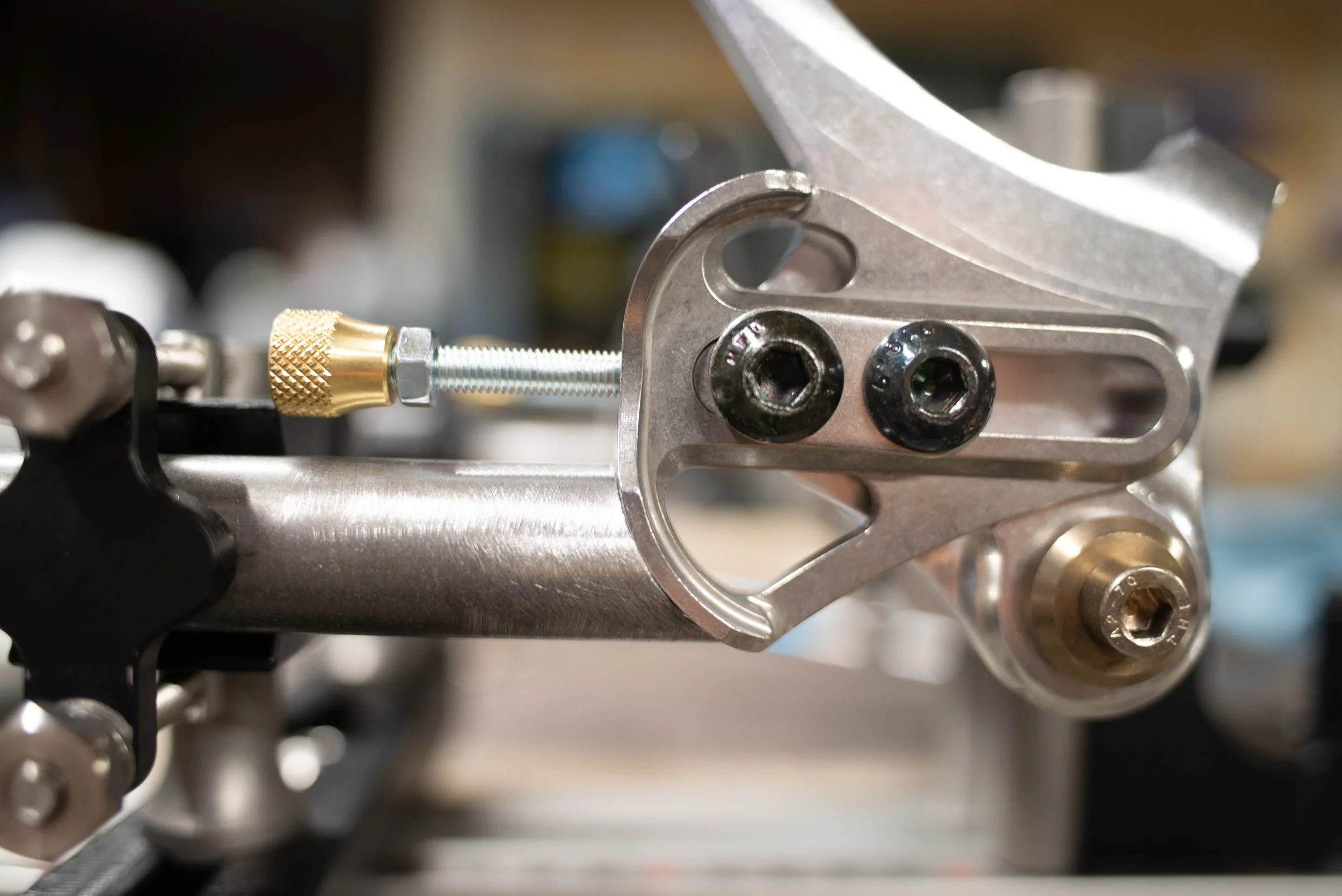

UDH dropout before brake mount

Forward facing seat tube cut (cut only finished after bike is finished to maintain round shape)

Seat stays coming next

All the steel pieces. The chainstays will be custom cut and bent out of the long dark tube

bottle bosses in the DT ready for solder

Soldered bottle bosses

Cutting the dropper post internal routing slot

Brazed-in dropper post routing, to be cleaned, cut, and detail arrow added later

Dry-fit

Dry-fit of front triangle ready to be tack welded

Ready to weld the chainstay

Chainstay setup

Tacked chainstays

Double-checking tire clearance (29x3.0" on 50mm rims)

Seat stays mitered and ready to weld

Welded, ready to blast

Welded, ready to blast

Cleaned and blasted

Cleaned and blasted

Cleaned and blasted

Painted

Painted. The serial number plate is first painted with the main color and then sanded back to a brass shine, leaving the embossed numbers in purple.

At the usual photoshoot site: Tunnel Drive. Wide, flat trails with stratified rock, a tunnel, and the Arkansas River, and all within a few minutes of town make this a prime spot for gravel and MTB photos

The finished product

The finished product